Hinges

Hinges are used in furniture and traditional machine construction as well as on other equipment, where they are mounted on doors, hatches and hoods, etc. Classic hinges are available made from plastic, aluminum, steel, sheet metal and stainless steel.

Industrial hinges by KIPP

The KIPP product range includes many different options of industrial hinges. Hinges connect two solid components so that they can move in relation to each other. Depending on the material, these are particularly sturdy, corrosion-resistant and user-friendly. Hinges are used in classic mechanical engineering, plant construction, on appliances and in industrial furniture construction. They are often installed on doors, hatches and covers as well as on frames and profiles. Thanks to the use of particularly resistant materials, some models are also suitable for demanding environments such as those found in maritime conditions.

Hinges - differences in material

KIPP offers many different types of hinges made from various materials.

Plastic hinges

Plastic hinges are know for their light weight. They are made of fibreglass reinforced thermoplastic and have a steel or stainless steel hinge pin. Due to the material, plastic hinges are particularly suitable for indoor use, or outdoor applications that are not directly exposed to weather conditions.

Aluminium hinges

Aluminium hinges are very versatile. Die-cast aluminium hinges are used for heavy doors, covers, housings and other indoor and outdoor applications.

Steel hinges

Steel hinges are more robust compared to plastic and aluminium hinges. As such, they can be used as heavy-duty hinges for reliable use on heavy doors and hatches. Due to the specific properties of the material, we recommend using steel hinges indoors only.

Stainless steel hinges

As they are corrosion-resistant and weatherproof, stainless steel hinges are ideal for outdoor applications. KIPP offers hinges in A4 quality for areas where higher corrosion resistance or seawater resistance is required.

Types of hinges

Different types enable use of KIPP industrial hinges in countless areas of application. Discover the wide range of different styles.

Standard hinges

Standard hinges by KIPP are very sturdy and ensure reliable operation. They cannot be lifted off or locked. They are available in different materials and sizes. This means that the appropriate type can always be selected for respective application and can be mounted quickly and easily. Some of them are also suitable for use as heavy-duty hinges.

Lift-off hinges

Lift-off hinges are similar in design to standard hinges. However, they can be lifted of, permitting covers, hatches and doors to be removed quickly. A distinction is made between right and left hinges. Whether the element can be opened to the left or right depends on the option selected.

Hinges with locking lever

Locking hinges have a clamping lever fitted to the hinge pin. This lever is used to fixate the hinge in any position. This means that e.g. maintenance hatches do not have to be held, but can be locked open. In our shop hinges with locking levers made of plastic or die-cast zinc are available.

Hinges with detent

Detent hinges engage in various positions and ensure that doors or hatches remain securely open. These hinges have a different number of pre-defined index positions depending on the model chosen. The torque required to overcome the engagement point of the hinge and thus release the detent also depends on respective product. KIPP offers hinges with detent function made of plastic and aluminium.

Hinges with adjustable friction

Hinges with adjustable friction, also known as torque hinges, enable the door to be positioned at any angle. The frictional resistance can infinitely be adjusted from 0 Nm to 1 Nm by cap screw. With the larger option, infinitely variable adjustment from 0 Nm to 5 Nm is possible. Compared to hinges with locking lever, these have no integrated clamping lever and therefore no interfering edges.However, a hex key is required for adjustment. Hinges with adjustable friction are available made of aluminium. Part of the KIPP range is a hinge with pre-set friction made of stainless steel for areas where infinite friction adjustment is not necessary.

In-frame hinges

In-frame hinges are characterised by their placement inside the object. This makes them invisible hinges with no interfering edges and opens up other possibilities in terms of construction and design. Invisible hinges or in-frame hinges are used in mechanical engineering and switch cabinet construction for example.

Weldable hinges

KIPP weldable hinges facilitate welding due to materials selected and the specific material thickness. This permanent connection between the fixed and the movable object means that they can be used as heavy-duty hinges. There are special weldable hinges made from stainless steel that are acid and seawater resistant. As these have high load-bearing capacities, they are also suitable for use on ships to ensure safe movement of massive doors and hatches.

Spring hinges

Spring hinges by KIPP are fitted with a spring and are used to automatically open and close doors and hatches. The torque required to move the spring varies depending on the type of spring hinge. They are available as steel or stainless steel hinges with a visible spring or as aluminium hinges with a spring integrated into the body.

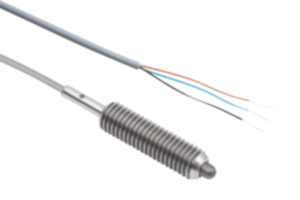

Security hinges

Security hinge switches are also part of the KIPP range. They are used to monitor the position of hinged safety hatches, protective covers and safety doors. The switching angle of these hinges is freely adjustable. They signal only after a certain degree of movement. The information about the current open status can be displayed directly, e.g. on the monitor of a programmable logic controller (PLC).

Buy hinges from KIPP online

Purchase your hinges directly from KIPP's online shop. Trust in years of experience and be convinced by our products. If you are unable to find a suitable hinge for your application, please contact us. Upon request, we are able to develop customised solutions tailored to your needs.